Polywires can be spliced using crimping sleeves or making a joint. However, it’s recommended to burn the ends of polywire and twisting the metal strands in order to make a secuer connection. Use can use any method but make sure that the joint is secure.

Whether you are using a poly rope or poly wire, we’ll guide you on how to tie poly wire together.

Here are some reasons why you may need to splice poly wires:

- If the poly wire spool ends midway.

- You want to extend the fence.

- Fence wire breaks, and you want to rejoin them.

How to splice poly wire electric fence?

If you want to splice two poly wires:

- If you want to splice polywires without using any tool, tie(knot) the ends of the polywires. Make sure a couple of inches from both wires is spare. Then burn the excessive ends of both polywires. Twist the filaments of both wires with each other. Burning the poly wire ends exposes the metal filaments & joining them improves electrical connection & current conductivity.

- If you are using crimp sleeves, pass both ends of poly wires through the opposite ends of the crimp sleeves. Then press the sleeve(shell) with the plier or crimping tool.

- Polywire connector is also used to splice poly wires. It has two meal plated joined with bolts. Polywire is passed between both plates & the bolts are tightened.

Tools Required:

- Method 1: Making a simple knot. No tools are required except a lighter/match.

- Method 2: Crimp sleeves & crimping tool

- Method 3: Polywire Connectors (Optional)

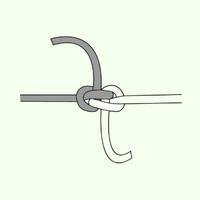

Method 1: Splice poly wire/rope making a knot

The most cost-effective DIY method to splice poly wire is making a knot between both ends of the poly wire.

- Make a sturdy knot between both ends of the poly wire. Don’t over-stretch the wires as it may cause the conductive metal filaments inside to break.

- Make sure a few inches are spare after making a knot from both ends of poly wires.

- Burn both ends of the poly wire using a lighter. The polyethylene will melt, exposing the metal strands. Twist the metal strands of both poly wires with each other & wrap them over a poly wire.

- This step is quite important because the poly wire is made of polyethylene rope with metal strands woven inside. Making a direct knot(joint) may result in a poor electrical connection between the metal filaments of both poly wires, which results in higher resistance & ultimately, a weak fence.

Tips:

- The fence shouldn’t have a lot of knots (joints) or splices. A weak joint may cause voltage drops in your fence. Also, extra hanging wires from joints can cause short circuits.

- Burn the extra poly wire ends after the joint for a smooth and secure finish.

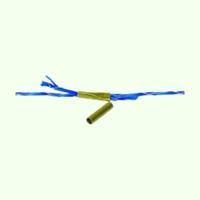

Method 2: Splice poly wire using crimping sleeves

Depending on the wire’s diameter, choose the right crimping sleeves. Polywire/rope crimping sleeves are made of brass or steel, hence are excellent conductors. As per my experience copper or brass crimp sleeves are ideal as they also improves current conductivity. Use 2-3 crimp sleeves per joint. Crimp sleeves are quite cheap & generally costs around 10 $ per 100 pieces.

Steps to connect poly rope electric fence:

- Turn off the fence charger

- Bring the poly wire ends close.

- Pass both poly wires through the opposite holes of the crimping sleeves.

- Tighten the fence wire. Adjust the crimping sleeves at the right spot.

- Compress the crimp sleeve using pliers or a crimping tool.

In another way:

- Burn the ends of both poly wires to expose the thin metal filaments.

- Pass a wire through the crimp sleeve.

- Gently, make a knot between the metal filaments of both wires.

- Adjust the crimp sleeve over the knot.

- Press the sleeve with the plier or a crimp tool.

Installing crimp sleeves over bare filament knot ensures better current conductivity.

Tips:

Using crimp sleeves specifically designed for poly wire or rope.

Don’t leave extra wire to hang after installing crimping sleeves, as it may cause short circuits. Burn the ends and twist the metal strands to ensure better connectivity.

Method 3: Splice wires using a poly wire connector

Although poly wire connectors are a little costly(around .8$ per piece), but they are specially designed to join(splice) poly wires. These connectors are removable & can be reused hence serves for a very long time as compared to other tools. Poly wire connectors are made of galvanized steel hence they ensure proper current conductivity. A plate in the connector is screwed to tighten the fence wires.

To use them unscrew the bolts on the connector. It’ll lose the metal plates. Pass both poly wires through the opposite side of the connector, between the plate. Screw the bolts again, and the poly wire will be fastened in the poly wire connector.

Conclusion

Joining poly wires is easy: burn the poly wire ends or twist the metal strands. You can also use a crimping sleeve or poly wire connector.

But frequent joins in the poly fence wire could result in loose connection, conductivity, and voltage drop in the fence.

If you still need any assistance, ask us in the comments.

Related Guides: